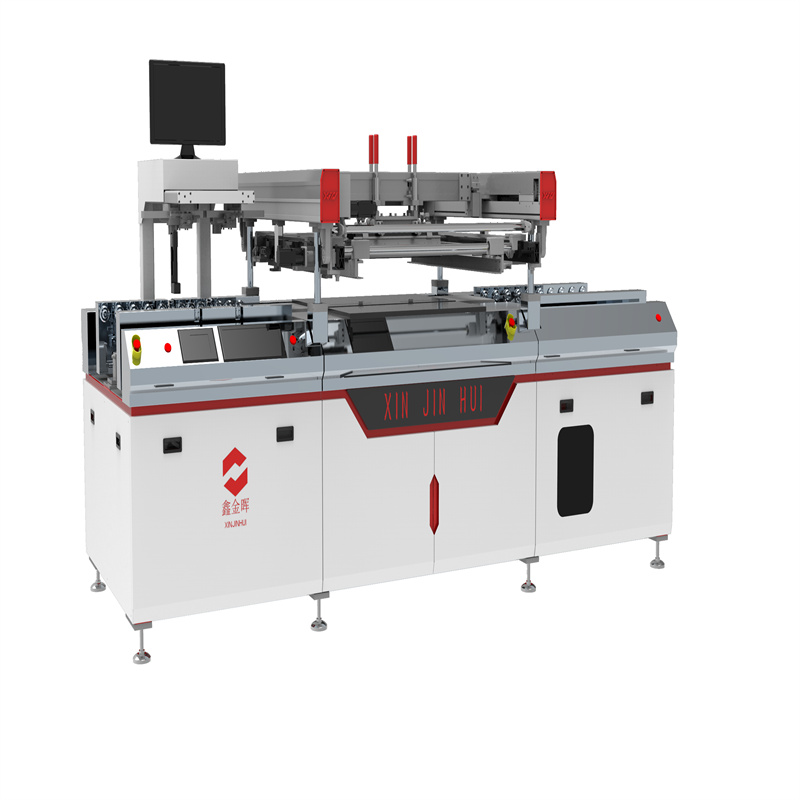

Otomatiki smart sirika screen kudhinda muchina

PCB solder mask printer, pcb legends printer, girazi silk screen kudhinda, solar silk screen kudhinda, pvc, movbile chivharo uye zvichingodaro.

Muchina wose unoumbwa nechikamu chakangwara cheCCD system alignment chikamu, chikamu chekudhinda uye chikamu chekudzoka kwezvinhu, nechekuruboshwe nekurudyi tafura yekuvhara pakati kuti ifambise zvikamu zvakadhindwa mumutsara.Inokodzera solder mask/character inki kudhinda.

1, Kumisikidzwa kwekudya kunotora yakazara-servo otomatiki ndiro inofananidzira system, uye iko kurongeka kunosvika padanho reum.

2, Servo mota inodhinda kudhinda uye pneumatic off screen kuti ione synchronous off screen function uye zvinobudirira kudzivirira screen kunamira.Iyo servo mota inotyaira chidimbu chekudhinda kuti chifambe nekukurumidza uye mushe kuti ive nechokwadi chekumisikidzwa kwechidhindo chekudhinda.

3, Servo mota uye yakanyatso kutungamira njanji dhizaini inovimbisa kumira kwakaringana uye hupenyu hurefu hwebasa.Iyo yakatwasuka yakatwasuka yekusimudza chimiro chedhindiro furemu inovimbisa kuti kudzvanywa kweiyo scraper kwakaenzana.

4, smart interface kubata mashandiro, nyore kuseta, uye otomatiki kuona kukanganisa uye kugadzirisa dambudziko.Kudhinda kudhindwa uye ndiro yekrini inogona kugadziriswa zviri nyore uye zvakarurama, uye kona ye scraper inogona kugadziriswa pakuda.

5, CCD mufananidzo otomatiki alignment system, yakasanganiswa nekuruboshwe uye kurudyi inomhanya mapuratifomu, inogonesa kukurumidza kushanda uye yakakwirira kurongeka kwechokwadi.Iyo yakawanda kukosha kwekugadzirisa kweiyo mufananidzo system haina kuganhurirwa nechero giraidhi, uye chero mifananidzo inogona kushandiswa sechinangwa.

6, Discharge chikamu

Chikamu chekuburitsa chine discharge conveying rollers kuti utore treadmill wouya nayo mu base plate, woidzosera kune conveyor.

Iyo dhizaini iri pamusoro yakavakirwa papfungwa ye "hungwaru yekubatanidza mashandiro", uye neyakachinjika maconveyor ari kumberi uye kumashure zvikamu, iyo yekupinza manpower inogona kuderedzwa zvakanyanya uye kugona kwekugadzira kunogona kuwedzerwa.

PLC: Mitsubishi

Gwaro renjanji:THK

SilindaAIRTAC

Kukurukurirana:Mitsubishi

Bata sikirini:weinview

Synchronous belt:MEGADYNE

Bearing:NSK

Ball screw:TBI

Saizi yepamusoro yekugadzira:630 mm × 730mm

CCD alignment lens:4

Minimum processing size:350mm

× 400mm

Kugadziriswa kweCCD:130

Board ukobvu range:0.8

-4.0mm

Kugadziriswa kweCCD:12um

Sipidhi yekudhinda:30~300 mm/sec inochinjika

CCD kushanda range:300-720mm

Yakanyanya skrini furemu saizi:1200 × 1100mm

CCD inobudirira nzvimbo yekuona:12*15mm

Minimum screen furemu saizi:800 × 800mm

CCD yekufungidzira saizi yechinangwa:1-3mm

Iyo diki plug hole dhayamita:

≤ 0.20mm

Mhando dziripo dzeCCD zvinonangwa:unlimited

Kurongeka kwetafura yepamusoro:±0.1mm/m2

Kurongeka kwekufananidzira kweCCD:0.01mm

Kurongeka kwegomba:± 0.02mm

CCD imaging kudzika kwemunda:0-2mm

8-point clamping nzvimbo yekumisikidza uye CCD otomatiki chinzvimbo

Squeegee pressure kufanana:≤5kgf

Kuvhara / kukwesha kona:

±15°

Kudhinda kureba:0~10 mm

Scratch stroke:servo 0~900 mm inogadziriswa

Kubviswa kubva pabhodhi:0~10mm

Plug hole pad dhizaini:yakakamurwa kuita zvidimbu zvitatu

Kugadziriswa kwakanaka kwescreen frame:X, Y, θ±5mm

Equipment power:5.6/ KWH